|

Lien Yu Machinery CO., LTD.

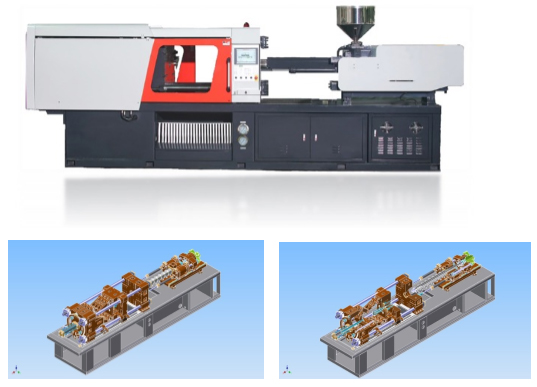

NH Series-Two Pattern Machine

1. Be more save while moving molds.

While implementing and removing molds, molds do not need to ascend high. The height could decrease down to merely 1 meter; yet the action could not interfere by tie bars. Meanwhile, machines do not have to be lowered.

2. Capacity upgrade.

Rotation prevention pins are screw into corresponding holes, which makes tie bars keep rotate smoothly when movable platen mobiles. The speed increase at least 10%.

3. Tie bar life time extension.

Due to the reasonable gap maintain between tie bars and the inner of movable platen base, when movable platen base shifting, it could do slight sway to adjust tie bars’ movement. As a result, tie bars are able to slide more smoothly and are uneasy to get scrub and damage during the long-term usage.

4. Pressure on molds decrease.

Tie bars and position mesons are assembled on the fixed mold holder. During the action, the mold holder could do slight sway to adjust tie bar’s movement, which could decrease the pressure on molds and enhance the life time of molds.

5. Power-Saving.

There are three set of rotation prevention structures in the connection of fixed platen and three tie bars, movable tie bar is not included. The structure is to keep tie bars rotating flexibly. Compare with traditional structure, with the same power, the new structure can reduce more consumption and reach more capacity with the same power.

6. Maintain time saving.

With the larger space between molds and movable tie bar (, which could reduce four tie bars to three tie bars), operators could remove or implement molds at the space between fixed mold and movable platen.

TF Series

1. Thicken Patens.

Patens become more reinforced; therefore, as machines work, patens would not move, which reduce interferes on tie bar.

2. Extend tie bar gear nuts into adjusted molds patens.

Extend tie bar gear nuts into adjusted molds patens. The depth reaches half of patens. The way is able to support tie bar and ease the pressure from patens on tie bars.

3. Toggles.

The structure of toggles was converted into four branches, which enable to improve the stability. Additionally, according to the idea of torque, if changing the length of toggle, the action would require less power, yet rises the speed. The new development apparently shrink the cycle time.

4. Injection Movement.

The firmly injection basement with two cylinders makes the motion smoother.

5. Double pulling pistons.

Two pulling pistons were placed at each side to balance the force of injection.

6. Appearance.

With the outstanding design of curved steel metal cover and no-welding frame cover, the machine combines aesthetics and strength.

Contact Person: Mei-Ching Huang

Email: meiching.hh@gmail.com

Tel: 886-2-2728446

Fax: 886-2-2428023

Website: www.ly-inj.com.tw

|